Abstract

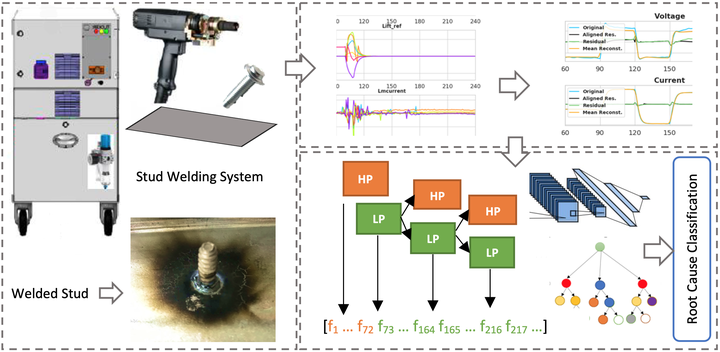

Arc stud welding is a well-developed and automated manufacturing process commonly used to fasten studs to a workpiece. This process requires implementation of measures to prevent low-quality welds that can lead to disposal of an entire structure. In this paper, a machine learning-based method is introduced that uses experimental data to detect and classify defective stud welds. the source of data is a series of experimental arc stud welds conducted by a precision robotic arm. Welding data log is recorded through various sensors to shape a multivariate dataset for arc stud welding. Then, wavelet transforms as well as synthetic signal generation are applied for feature extraction. For each set of extracted features, suitable models are designed, trained, and evaluated for automatic root cause classification. Next, the models and approaches are compared on synthetic measurement generation, feature extractions, and feature importance. Numerical results show that XGBoost, the best model, has 85.41% F1-score on the test set. Additionally, the study reveals that voltage and lift play crucial roles in the root cause classification of arc stud weld. The proposed method not only offers promising results for defect detection in arc stud welding but also provides outreach value for similar industrial processes.